Getting The Digital Printing To Work

Corrugated paper can often verify to be a difficult surface to print on, but Litho prints to a different surface area and is after that laminated to it, making it simple to publish high-quality pictures. It can be very regular, also for long terms. Actually, the more you publish, the less costly the costs come to be for Litho.

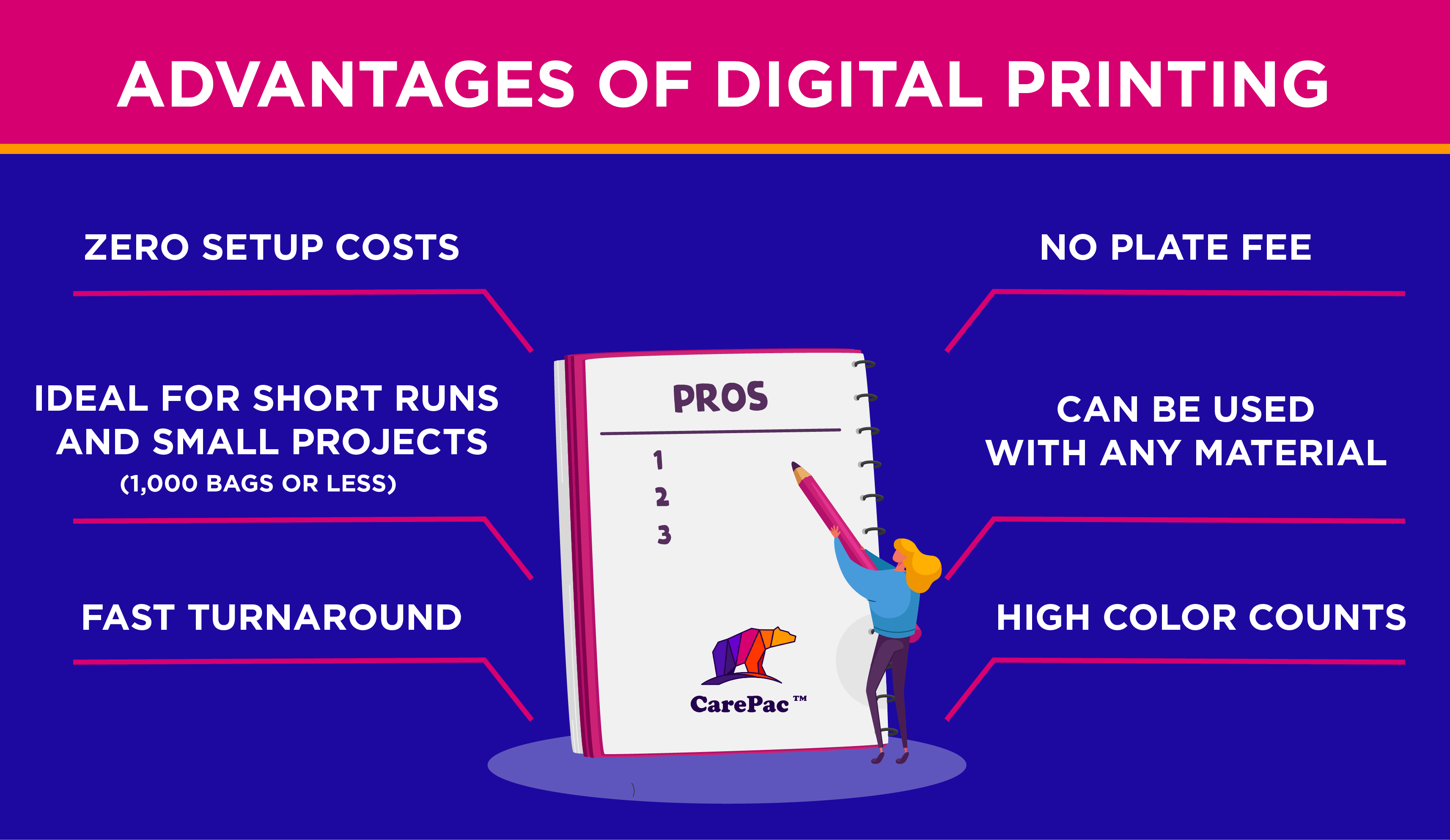

If you have sufficient time and spending plan, and a large quantity of a single style, then there should not be a problem. What Litho does not give you is exactly what Digital does, customization. Extra on that particular later. Expensive established Longer turn-around No Variable Data Printing Smaller color range, colors can be less brilliant Digital printing is the procedure of printing electronic pictures directly onto the corrugated substratum using a single-pass, direct-to-corrugate method - Digital Printing.

Some Known Details About Digital Printing

Traditional printing methods like Offset Printing have actually been the status quo for some time, and one of the most significant factors is that at large quantities, it wins on expense. That's if you plan to utilize a solitary layout for all of your product packaging - those days are over.Offset Printing calls for time and money to develop a Printing Plate, while Digital Printing enables you to just submit an art file( as several as you desire )to the Press. Variable Information Printing (VDP)Print-on-demand Special item styles Seasonal+Marketing messaging Cost-effective short manufacturings Quicker turn-arounds If your job has a single design, Litho might be a far better option due to the scaling expenses of manufacturing.

We provide every little thing from plain brown delivery boxes to sophisticated, high-graphic published point-of-purchase display screens and whatever in between. They vary in dimension and modern technology, but they enable you to post art files straight to the press, as opposed to creating printing plates. Digital Printing is when you print a digital-based picture onto some kind of print media.

Comments on “The smart Trick of Digital Printing That Nobody is Talking About”